Ongoing Research Projects

Identifikation & Regelung

-

Electromagnetically actuated PunchThe challenge of this research joint research project with the institute of metal forming and metal forming machines is the design and control of an electromangetically actuated punch. This drive concept allows the adaption of the cutting process and, therefore, gives the possibility to compensate oscillations and tracking errors during the cut. Thus, a higher stroke rate, better quality of the produced elements, and lower tool wear level of the die can be achieved. Up to now, rates up to 50 strokes per second and cutting forces up to 10 kN were reached. Thanks to the direct drive concept a very compact construction is possible.Team:Year: 2010Funding: German Research Foundation (DFG)

![]()

![]()

-

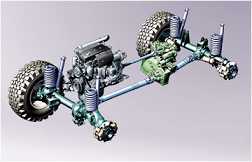

Vehicle Vibration Analysis and CompensationA current project at imes is dealing with vehicle oscillations in automobiles. The research plan aims to find and analyze causes of vibration in the vehicle, in order to take appropriate measures – control strategies – to reduce or avoid vibrationsTeam:Year: 2011Funding: IAV GmbH

![]()

![]()

-

Development of a Miniaturized, Electromagnetically actuated PunchIn this joint research project with the institute of metal forming and metal forming machines a small, efficient electromagnetically actuated punch for cutting thin metal sheets is developed. By exciting the mass-spring-system specifically at its resonance frequency a compact, efficient high speed punch machine is optained, saving space, energy and time.Team:Year: 2014Funding: German Research Foundation (DFG)

![]()

![]()

-

Robust estimation of vehicle's side-slip angle, based on sensitivity-based parameteradaption and nonlinear observer structuresA resent project at the Institute of Mechatronic Systems adresses the estimation of relevant parameters and states of lateral dynamic systems in vehicle dynamics. Therefore different modelbased observers, based on sensitivity-based parameteradaption are realised to ensure a robust Estimation.Team:Year: 2014

![]()

![]()

-

simTrailer - Complete, Model-based State Monitoring of TrailersIn the simTrailer project, online-capeable methods for model-based state monitoring of trailers are being developed to ensure the most efficient use of sensor technology.Team:Year: 2017Funding: BPW Bergische Achsen KG

![]()

![]()

-

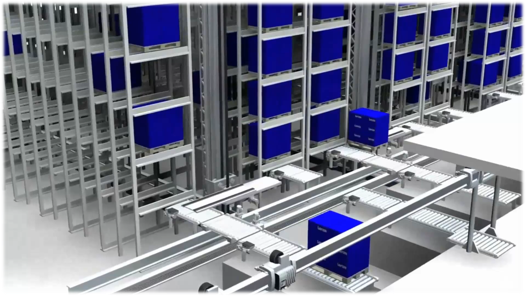

Condition Monitoring of nonlinear plants in the automation industryThe progressive networking of industrial plants provides an increasing amount of data that is available in operation. It is usually no longer possible for humans to oversee this amount of information and to draw knowledge from it. With the development of increasingly powerful processors, machine learning methods have come into focus for this application. In this project, the existing procedures, which are mostly based on physical models, are to be complemented in order to enable comprehensive monitoring. The focus is on nonlinear systems that are difficult to describe using physical models.Team:Year: 2019Funding: Lenze SEDuration: 10/2018 - 09/2022

![]()

![]()

-

Planning and Optimization of Vehicle Speed TrajectoriesRegarding the growing in automation of road traffic, prospectively driving distances will be increasingly covered with the support of driver assistance systems in the future. Against this background, increasing the energy efficiency of partially automated vehicle guidance is becoming increasingly important. This research project aims to make semi-automated vehicle guidance more energy-efficient by planning and optimizing a speed trajectory. In doing so, individual vehicle guidance preferences must be taken into account in the conflicting goals of a short travel time and a low energy demand. In addition to specific vehicle characteristics, predictive route information (e.g. altitude topology, speed limits and curve radii) for the upcoming route section (long range) is used for speed optimization. In addition, it is intended to dynamically react to unpredictable events (such as vehicles driving ahead or unmapped speed limits) on short prediction horizons (short range). The goal is the development of a real-time capable model predictive control method, with which the vehicle longitudinal control is performed energetically optimal for each individual driver.Team:Year: 2019Funding: IAV GmbHDuration: 12/2019 - 11/2022

![]()

![]()

-

RekuTrAxZiel des Projektes RekuTrAx ist die Entwicklung einer hochintegrierten Rekuperationsachse für LKW-Trailer. Rekuperation, die Rückgewinnung von elektrischer Energie bei einem Bremsvorgang, ist eine Technik, die für die Reduktion des Energieverbrauchs von Fahrzeugen genutzt wird. Der elektrische (Hilfs-)Antriebsstrang erlaubt direkt eine Rekuperation, ohne dass zusätzliche Hilfsmittel genutzt werden. Anders sieht es bei Fahrzeugen aus, die mit fossilen Brennstoffen oder Brennstoffzellen betrieben werden. Hier ist eine Rekuperation direkt über den Antriebstrang nicht möglich. Dieser Ansatz hat bei LKW-Trailern aufgrund der hohen kinetischen Energie besonders hohes Potenzial, Ziel ist es daher, die Rekuperationsachse eines LKW-Trailer unabhängig von der Zugmaschine nutzbar zu entwickeln. Das Projekt wird in Zusammenarbeit mit dem KIT sowie den Unternehmen REFU Drive GmbH und BPW Bergische Achsen KG bearbeitet. Die Schwerpunkte des imes liegen bei der Entwicklung eines intelligenten Energiemanagements sowie dem Condition Monitoring.Team:Year: 2022Funding: BMWKDuration: 08/22 - 07/25

![]()

![]()

Finished Research Projects

Identifikation & Regelung

-

Time-Optimal Control of Electromechanical ActuatorsSeveral electromechanical actuators are used for a exhaust gas recirculation in diesel engined passenger vehicles. These actuators regulate the exhaust gas ratio with a high dynamical behavior. To account for the bounded power supply different model based control concepts are implemented within this research projectFunding: IAV GmbH GifhornDuration: 11/2012-10/2013

![]()

![]()

-

Analysis of vehicle drive-train vibrationsA current project is the analysis of vehicle drive-train vibrations in the powertrain of a passenger car. The aim of the research project is to analyse individual phenomena and identify their causes. This knowledge can be used in order to find suitable software or hardware measures that reduce or avoid this vibrations. This work is being carried out as part of an industrial project with IAV GmbH.Team:Year: 2015Funding: IAV GmbH

-

iTracC - Intelligent Traction ControlThe goal of the iTracC project is to increase driving safety in vehicles with electrified powertrains by optimizing traction control based on adaptive powertrain and friction models.Team:Year: 2015Funding: Bundesministerium für Wirtschaft und Energie (BMWi)

![]()

![]()

-

Remote Mechatronics ChallengeRemote Laboratories allow the control and observation of a real test bed via the Internet. Thus, lecture contents can be deepened and applied to real test beds. In addition to the permanent availability, the limitation of defined parameter of the system is a great advantage over classical laboratory concepts.Team:Year: 2016Funding: Studienqualitätsmittel

![]()

![]()

-

Online-Identification of control parameters in electric drives for parameter tracking IIThe main goal of the project is the identification of the main parameters for electric drives with elastically coupled mechanics without additional sensors. This is achieved firstly with dedicated identification trajectories and secondly during operation by observing the parameter identifiability with respect to the features of the trajectory. The basis is a mechatronic model of the overall mechatronic system.Led by: Prof. Dr.-Ing. Tobias OrtmaierTeam:Year: 2017Funding: Arbeitsgemeinschaft industrieller Forschungsvereinigungen „Otto von Guericke“ e.V. (AiF)Duration: 07/2017-01/2020

![]()

![]()

-

RoCCl - Road Condition CloudAs part of the DFG-funded project RoCCl, a time-varying map, the Road Condition Cloud, is developed in cooperation with the Institute of Automotive Engineering of the TU Braunschweig. Therefore the road condition with additional confidence will be estimated by probability-based data fusion of various heterogeneous information from onboard and environmental sensors and transferred to the card. The communication with the RoCCl thus offers the possibility to correctly initialize driver assistance systems with regard to the current road condition at any time.Team:Year: 2018Funding: Deutsche Forschungsgemeinschaft (DFG)Duration: 02/2018 - 01/2021

-

Automated commissioning of electrical drive trains - Use of temporary commissioning sensorsIn order to gain detailed models for the automated design of feedback and feedforward control, prior knowledge can be combined with structure and parameter identification in various ways. It is currently already possible to identify models of electric drives by means of experiments and to use them for control design, Kalman filtering, online state and parameter estimation, etc. The problem remains that the uniqueness of the structure identification is not always given. As a possible solution, temporary commissioning sensors could be used, such as load-side position sensors, accelerometers, strain gauges, yaw rate sensors, and so on. However, little research has been done on how the position, type and quality of the temporary sensors contribute to solving the ambiguity problem and to improving the accuracy of the models. In addition, there are hardly any approaches for the systematic assessment of structure distinguishability. Research objectives: 1.) Higher quality and robustness of the techniques from previous projects due to temporary commissioning sensors 2.) Reduction of commissioning time by identification of the mechanical plant 3.) Commissioning box (low-cost hardware, or smartphone app) 4.) Broad field of application through automatic selection of the model structure 5.) Evaluation of the benefits of temporary commissioning sensors The temporary sensor can be reused after commissioning on other testbeds, or otherwise the expenses are affordable, as low-cost hardware is used. The methods developed are to be validated on various testbeds and integrated into the e-Workbench (FVA 827)Led by: Prof. Dr.-Ing. Tobias OrtmaierTeam:Year: 2020Funding: FVADuration: 02/2020-02/2021

![]()

![]()

-

Automated Control Design based on (partly) automatically generated, Control-otpimal ModelsModel-based control design enables objective, reproducible controller settings and, if required, online parameter adjustment. The controller is tuned according to simple calculation rules or by means of simulations without costly experiments. The difficulty, however, is to determine the appropriate model for a given system. When modeling, it is often not clear which physical effects must be taken into account in the model and thus in the model-based controller, or which effects can be neglected, e.g. elasticity, friction, dead time, slack. The decision on a suitable control concept (e.g. phase-lead network vs. notch filter, ...) also requires a lot of expert knowledge. In this project, (partially) automated models are to be selected and model-based controllers designed. Criteria such as maximum dynamics and minimization of the overshoot lead to different parameterizations. On the basis of these and other application-dependent criteria that can be specified by the user, an overall concept for the model and controller should be generated. As a result, a significantly reduced commissioning time can be expected with comparably good controller properties. The evaluation of the models for the model selection must be carried out based on control engineering criteria. This is in contrast to commonly used methods such as cross-validation and information criteria. Possible approaches arise from the area of model predictive control.Led by: Dr.-Ing. Hans-Georg JacobTeam:Year: 2021Funding: Forschungsvereinigung Antriebstechnik (FVA)Duration: 03/2021-02/2022

![]()

![]()