Ongoing Research Projects

Condition Monitoring of nonlinear plants in the automation industry

| Team: | M. Sc. Moritz Fehsenfeld |

| Year: | 2019 |

| Funding: | Lenze SE |

| Duration: | 10/2018 - 09/2022 |

| Is Finished: | yes |

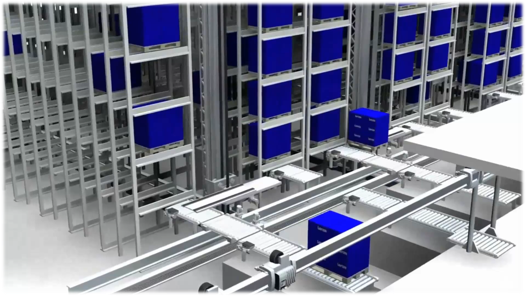

The progressive networking of industrial plants provides an increasing amount of data that is available in operation. It is usually no longer possible for humans to oversee this amount of information and to draw knowledge from it. With the development of increasingly powerful processors, machine learning methods have come into focus for this application. Algorithms are developed that recognize the pattern in the measurement data and can thus make predictions. In contrast to the models established in the industrial environment, they are not based on physical relationships, but on statistical evaluations of the available data. The knowledge obtained in this way can be used, for example, to model complex systems that cannot be described or can only be described with difficulty through physical relationships. A widespread application is the condition monitoring of plants, in which failures should be recognized at an early stage before failure occurs.

As part of the project with Lenze Automation GmbH, methods for fault detection are being developed that are used on machines with non-linear system behavior. The use of data-driven modeling to complement physical models is being investigated. An example of this is the monitoring of the pretension in the case of toothed belt drives. If the preload force drops, this can be recognized from the sensor data and a warning can be issued.

Lenze is a global automation technology specialist that provides a comprehensive range for many different areas of application. The company employs over 3700 people worldwide and is headquartered in Aerzen near Hameln.

Finished Research Projects

Condition Monitoring of nonlinear plants in the automation industry

| Team: | M. Sc. Moritz Fehsenfeld |

| Year: | 2019 |

| Funding: | Lenze SE |

| Duration: | 10/2018 - 09/2022 |

| Is Finished: | yes |

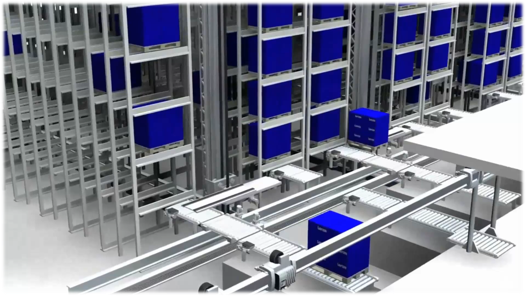

The progressive networking of industrial plants provides an increasing amount of data that is available in operation. It is usually no longer possible for humans to oversee this amount of information and to draw knowledge from it. With the development of increasingly powerful processors, machine learning methods have come into focus for this application. Algorithms are developed that recognize the pattern in the measurement data and can thus make predictions. In contrast to the models established in the industrial environment, they are not based on physical relationships, but on statistical evaluations of the available data. The knowledge obtained in this way can be used, for example, to model complex systems that cannot be described or can only be described with difficulty through physical relationships. A widespread application is the condition monitoring of plants, in which failures should be recognized at an early stage before failure occurs.

As part of the project with Lenze Automation GmbH, methods for fault detection are being developed that are used on machines with non-linear system behavior. The use of data-driven modeling to complement physical models is being investigated. An example of this is the monitoring of the pretension in the case of toothed belt drives. If the preload force drops, this can be recognized from the sensor data and a warning can be issued.

Lenze is a global automation technology specialist that provides a comprehensive range for many different areas of application. The company employs over 3700 people worldwide and is headquartered in Aerzen near Hameln.